Ordinary the amount and measurement of particles in Each and every area. Then take your locale averages and locate their regular, so you may have the overall normal measurement and amount of particles for the cleanroom.

The recovery exam evaluates the cleanroom’s capacity to Get better soon after disturbances or interruptions. This is particularly vital in assessing how speedily the cleanroom returns to its specified problems immediately after occasions for example doorway openings or other disruptions.

Want to learn which one of our particle counters will enhance your cleanroom contamination tactic and transform your generation? Learn currently.

A prompt and successful Restoration makes certain that the cleanroom maintains its expected cleanliness degrees throughout regime operations.

Class one hundred cleanrooms can be found in a large assortment of types and configurations that alter according to the company. Softwall and hardwall cleanrooms are the two simple kinds and the ones which might be most commonly used.

These resources are easy for casual shippers, but keep in mind that they supply only “estimated” classes. In the event you’re aiming to stay clear of freight reclasses, the sole way to make sure your class is to substantiate your freight class applying the correct NMFC code, and ensuring it can be visible and legible over the freight BOL utilized at time of pickup. Your LTL shipping pro can help you do that, as they must have use of the NMFC databases.

Sinks and drains aren't permitted in Grade A and B areas. The Grade B room of your respective GMP facility needs to be Geared up which has a particle monitoring system more info together with an alarm if restrictions are exceeded.

Some cleanrooms are saved at a beneficial strain so if any leaks manifest, air leaks out on the chamber as opposed to unfiltered air coming in. That is most typically the case in semiconductor manufacturing, the place even minute amounts of particulates leaking in could contaminate The full system, although everything leaking out wouldn't be destructive to the surrounding community[citation desired].

Liability will take into account the probability of the shipment being destroyed or stolen, or detrimental other adjacent freight – as well as the perishability or possibility of freight theft with the product.

FDA tips about the pharmaceutical cleanse area and supporting area upkeep in sterile manufacturing device.

Cleanrooms preserve particulate-absolutely free air in the usage of either HEPA or ULPA filters employing laminar or turbulent airflow website concepts. Laminar, or unidirectional, airflow units immediate filtered air downward or in horizontal course in a continuing stream in the direction of filters Situated on partitions close to the cleanroom ground or as a result of lifted perforated ground panels to become recirculated. Laminar airflow methods are usually employed across eighty% of a cleanroom ceiling to take care of regular air processing. Chrome steel or other non shedding materials are used to assemble laminar airflow filters and hoods to forestall surplus particles entering the air.

Particle levels are often examined utilizing a particle counter and microorganisms detected and counted by environmental checking approaches[make clear].

Consistent Charge of these factors is important for The steadiness of items plus the prevention of conditions that may market microbial expansion or compromise item excellent.

GMP expectations aim to reduce the potential risk of contamination from particles, microorganisms, and pyrogens through the preparing and sterilization of medicines and health-related equipment.

Barret Oliver Then & Now!

Barret Oliver Then & Now! Christina Ricci Then & Now!

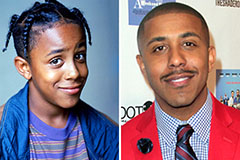

Christina Ricci Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Gia Lopez Then & Now!

Gia Lopez Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now!